Everywhere and Anytime

For continuous machine performance

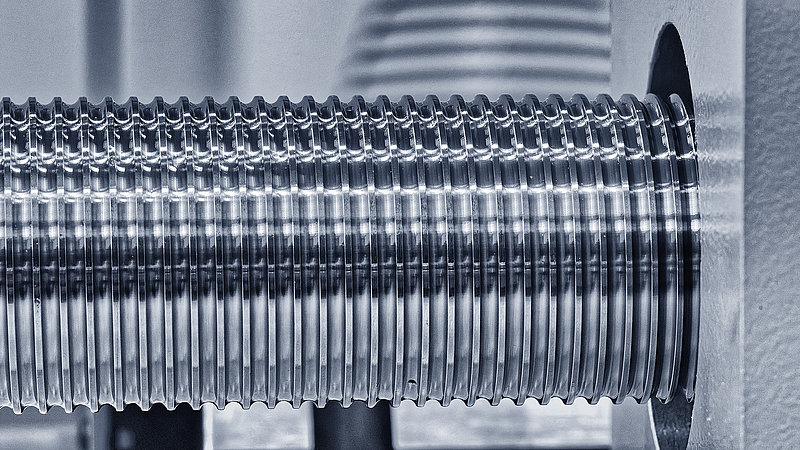

Roll grinding machines are designed for decades of operation. Regular inspections and continuous service activities are essential to ensure high precision, availability and efficiency in the production process in the long term.

As an established maintenance partner, we offer a comprehensive and clearly structured range of services to sustainably increase profitability in roll machining.

In addition to ensuring efficient grinding processes, you also receive clear inventory analyses, a basis for assessing machine life cycles and customized maintenance strategies to make the cost structure in maintenance more flexible and strengthen your market position.

Inspection & Studies

Safety Trough Inspections

Targeted machine inspections, taking into account the different characteristics of each machine type, identify potential problems at an early stage before they lead to costly machine downtimes.

Our trained specialists carry this out using machine-specific inspection lists and then draw up a detailed report. Taking your individual requirements into account, we then jointly identify the appropriate repair measures and recommended actions.

These findings form the basis for effective and economical maintenance planning with the aim of ensuring long-term high machine availability and quality of the end product.

Benefits:

- Optimized maintenance strategies

- Advance budgeting

- Increased operational reliability thanks to early identification of problems and proactive maintenance

- Well-founded investment decisions based on transparent condition analyses

Maintenance & Repairs

Your Machines in the Best Possible Hands

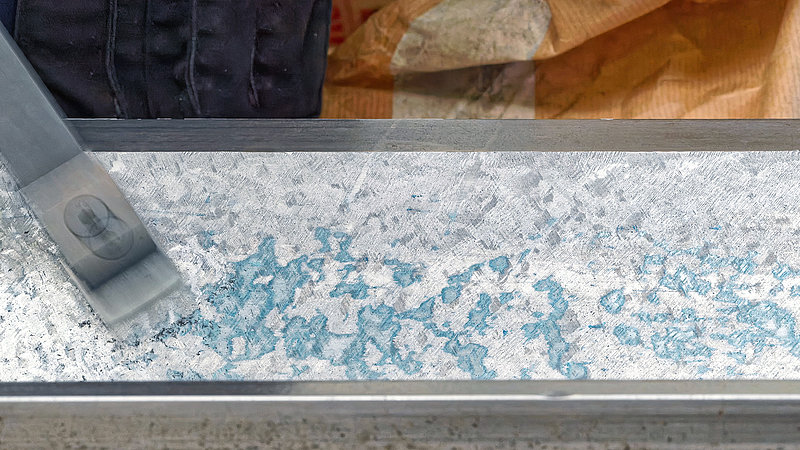

With our maintenance and repair service, you can maintain the functionality and reliability of your roll grinder. Our services range from regular maintenance work such as aligning and scraping machine axes, the installation of ready-to-install service kits on site, or the replacement of entire assemblies in-house.

We attach great importance to repairs that are in line with the current value of the machine and focus on machine components that retain their value.

Benefits:

- Quick reinstatement of machine availability

- Reduction of downtime to a minimum

- Professional repair according to OEM specifications using only high-quality components

Spare & Wear Parts

Fast, Safe, Reliable

The availability of spare and wear parts is essential for machine operating companies. Our aim is to provide fast, expert and unbureaucratic support in the event of a component failure. We supply both OEM components from the HerkulesGroup as well as other suitable spare parts. Thanks to our global network, we can guarantee prompt delivery of the necessary components of the required high quality. If certain spare parts are no longer available, we act flexibly and work out a viable alternative solution.

Your benefits

- Full functionality through the use of OEM spare parts or adequate substitutes for all machine brands

- Ensuring the long-term and reliable use of the grinding machines

Machine Relocation

Quick and Reliable Relocation

There are various reasons why a grinding machine may need to be relocated within the production facility or even to a new location. We take care of the planning, coordinated disassembly and reassembly, safe transportation to the new location and design the new foundation with adequate vibration damping.

We take all logistical aspects into account and ensure that your machine is ready for use quickly and efficiently at the new location.

Benefits:

- Professional planning and execution ensure the safe and efficient transportation of your machines

- Fast and precise relocations ensure that your production is interrupted as little as possible

- With special techniques and equipment, we guarantee the safe transportation of your valuable machines

Training & Application Technology

Strengthening Employee Competence

Expert machine operators and a well-trained maintenance team are the key to maximum availability and reliability of your roll grinders. To increase machine performance and reduce maintenance costs, we offer training programs for all roll grinder-related skills.

To ensure maximum practical relevance, all SBA training programs are designed as on-the-job training courses. Alternatively, theoretical training courses can be held at our training center on the company's own grinding machine. Our training programs are individually adapted to the customer's requirements and address all aspects of the work environment in order to fully exploit the potential of your grinder and your employees.

Benefits:

- Measurable and swift return on investment thanks to more efficient use of the grinding machines

- Increased operational reliability and long-term reduction in operating costs thanks to optimum machine operation

- Regularly trained and well-informed maintenance personnel carry out maintenance work to a first-class standard

Teleservice

Reliable Remote Service

Our grinder control system is equipped with a teleservice package that enables the fastest possible online fault analysis, diagnosis, and rectification in the rare event of a malfunction. Our specialists provide immediate troubleshooting assistance and process optimization without the need for time-consuming and costly travel.

Benefits:

- Expert support from our specialists all over the world

- Shorter downtimes and increased machine availability

- More efficient and faster fault diagnosis and rectification and spare parts procurement

- Reduced personnel costs for customer maintenance specialists

After Sales Service

Priority for Your Machine - Peace of Mind for Your Budget

SBA offers customer-specific after-sales contracts as an integral part of its services. Our customers benefit from coordinated services such as speedy troubleshooting, regular maintenance activities and warranty extensions for selected components. After-sales contracts guarantee you fast, uncomplicated, and cost-effective support from our specialists.

Your benefits:

- Fixed prices and therefore predictable costs for inspections, servicing, and maintenance work

- Integration of all maintenance and repair work into the agreement for safe operation